Call: 08045816914

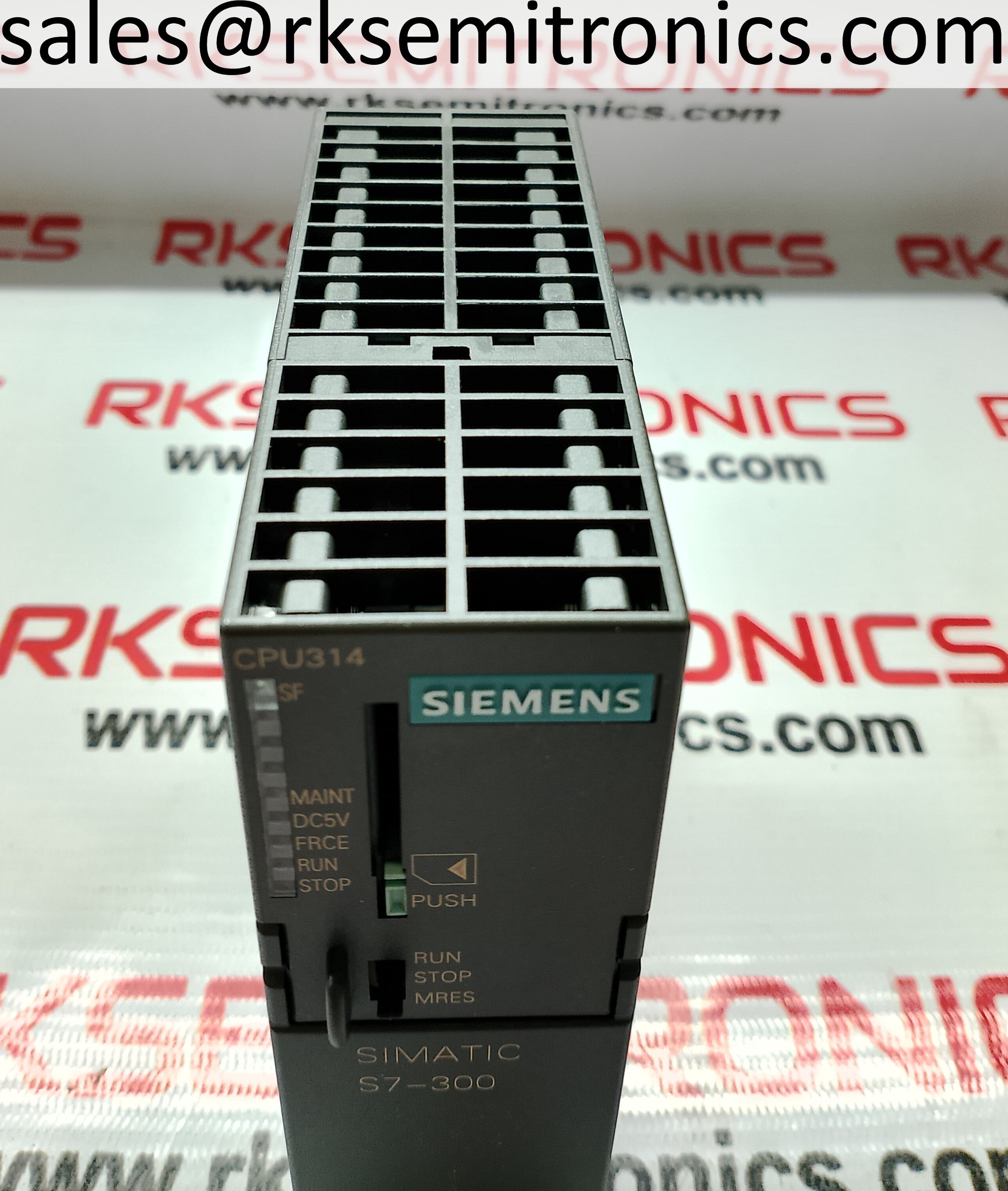

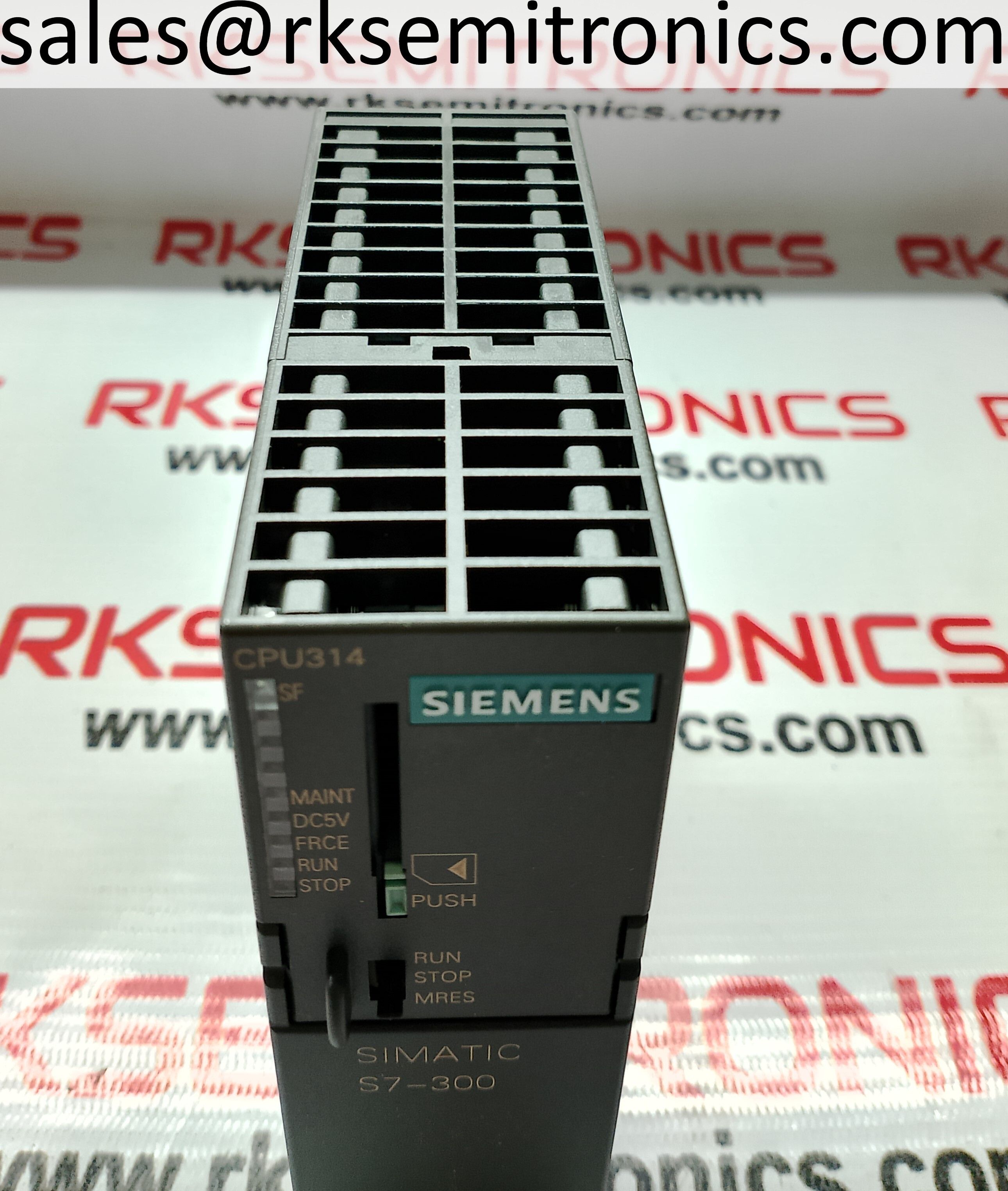

6ES7314-1AG14-0AB0 Programmable Logic Controller

Price 35000 INR/ Piece

MOQ : 1 Piece

6ES7314-1AG14-0AB0 Programmable Logic Controller Specification

- Display Type

- Status LEDs

- Processor Speed

- 0.1 s/operation (Boolean execution time)

- Features

- Modular design, expandable, integrated MPI/DP, user-friendly programming

- Response Time

- Processor cycle time: 0.1 ms/instruction

- Power Supply

- 24V DC external supply

- Operating Temperature

- 0C to +60C

- Resolution

- Depends on I/O module used

- Output

- Digital and Analog, modular expansion possible

- IP Rating

- IP20

- Interface

- MPI/DP interface (built-in), expansion possible

- Components

- CPU 314-1AG14-0AB0 Main Unit

- Sensors Specification

- Compatible with external digital/analog sensors via I/O modules

- Usage

- Industrial automation systems

- Input

- Digital and Analog, modular expansion possible

- Power Source

- External 24V DC supply

- Product Type

- SIMATIC S7-300 CPU 314 controller

- Application

- Factory automation, process control systems, machine controllers

- Rated Voltage

- 24V DC

- Supply Voltage

- 24V DC

- Size

- Standard modular size for S7-300 series

- Dimension (L*W*H)

- 125 x 40 x 130 mm (L*W*H)

- Function

- Programmable Logic Controller (PLC) for automation and process control

- Color

- Black / Grey

- Weight

- Approx. 600g

- Current Rating

- Max. 3A at 24V DC (depends on connected modules)

- Capacity

- 48 Kbyte Work memory

- Thickness

- Standard modular housing (approx. 80 mm depth)

- Frequency

- Operating frequency up to 10 MHz (internal processing)

- Protection Class

- Class 1, as per VDE 0106

- Isolation

- Optically isolated inputs/outputs (via I/O modules)

- Backup

- Memory retentive with battery

- Mounting

- DIN rail mounting (standard S7-300 rail)

- Relative Humidity

- 5% to 95% non-condensing

- Number of Communication Interfaces

- 1 MPI/DP combined interface

- Supported Protocols

- MPI, PROFIBUS DP

- Module Expansion

- Up to 32 modules (central configuration)

- Programming Software Compatibility

- STEP 7 (TIA Portal, Classic)

- Clock

- Real-time clock integrated

- Memory Type

- 48 KB Work memory, optional load memory via MMC

6ES7314-1AG14-0AB0 Programmable Logic Controller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About 6ES7314-1AG14-0AB0 Programmable Logic Controller

HW functional status 01Firmware version V3.3Engineering with Programming package STEP 7 V5.5 + SP1 or higher or STEP 7 V5.2 + SP1 or higher with HSP 218Supply voltageRated value (DC) 24 Vpermissible range, lower limit (DC) 19.2 Vpermissible range, upper limit (DC) 28.8 Vexternal protection for power supply lines (recommendation) 2 A min.Mains buffering Mains/voltage failure stored energy time 5 ms Repeat rate, min. 1 sInput currentCurrent consumption (rated value) 650 mACurrent consumption (in no-load operation), typ. 140 mAInrush current, typ. 3.5 AIt 1 AsFlexible Expansion and Integration

The 6ES7314-1AG14-0AB0 PLC enables up to 32 modules in a central configuration, providing extensive digital and analog I/O options. It supports integration with external digital and analog sensors, offering seamless scalability for complex automation tasks.

Reliable Performance for Industrial Automation

Engineered to operate reliably from 0C to +60C and in up to 95% relative humidity (non-condensing), the PLC utilizes optically isolated I/O (via modules) and meets IP20 and VDE 0106 protection standards. Memory is retained with a battery to ensure continued operation during power interruptions.

User-Friendly Programming and Maintenance

Configuration and programming are streamlined with STEP 7 software (compatible with both TIA Portal and Classic). Status LEDs provide clear real-time diagnostics, and modular housing allows for easy maintenance, upgrades, and replacement without disrupting the whole system.

FAQs of 6ES7314-1AG14-0AB0 Programmable Logic Controller:

Q: How is the 6ES7314-1AG14-0AB0 PLC installed in industrial settings?

A: Installation is straightforward, utilizing the standard S7-300 DIN rail for mounting within control cabinets. Its modular housing allows for efficient integration and straightforward expansion by adding compatible modules as required.Q: What programming environments are compatible with this PLC?

A: The 6ES7314-1AG14-0AB0 is fully compatible with STEP 7 software, including both the TIA Portal and Classic versions, making it easy for users to program, configure, and diagnose the controller as well as its connected modules.Q: When should I use this PLC in my automation system?

A: Choose this PLC for medium to large factory automation, process control systems, and machine controller applications that require reliable performance, communication flexibility (MPI/DP), and scalable I/O expansion.Q: Where can modular expansion be applied in the 6ES7314-1AG14-0AB0?

A: Up to 32 additional modules, including digital and analog I/O modules or communication processors, can be attached directly to the CPU unit in a central configuration, allowing customization for your applications demands.Q: What process ensures data retention during power loss?

A: The controllers work memory is battery-backed, providing memory retentive functionality even during power outages. An optional load memory via MMC further secures user programs and data.Q: How does the PLC support various industrial communication protocols?

A: A built-in MPI/DP interface enables connectivity to other devices using MPI and PROFIBUS DP protocols, supporting integration with a wide range of industrial networks for data exchange and coordinated control.Q: What are the main benefits of using the 6ES7314-1AG14-0AB0 PLC?

A: Key advantages include modular, expandable architecture, robust performance in industrial environments, easy programming with familiar software, and strong data retention and diagnostics features, all of which enhance system reliability and flexibility.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Programmable Logic Controller Category

6ES7321-1BH02-0AA0 Programmable Logic Controller

Price 8500.00 INR / Piece

Minimum Order Quantity : 1 Piece

3UG4513-1BR20 voltage Monitoring Relay

Price 17000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : PLC

Application : Electric

6ES73311KF020AB0 PLC

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : PLC

Application : Electric

6ES7321-1BL00-0AA0 Siemens PLC Module Simatic S7-300

Price 37999.0 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry